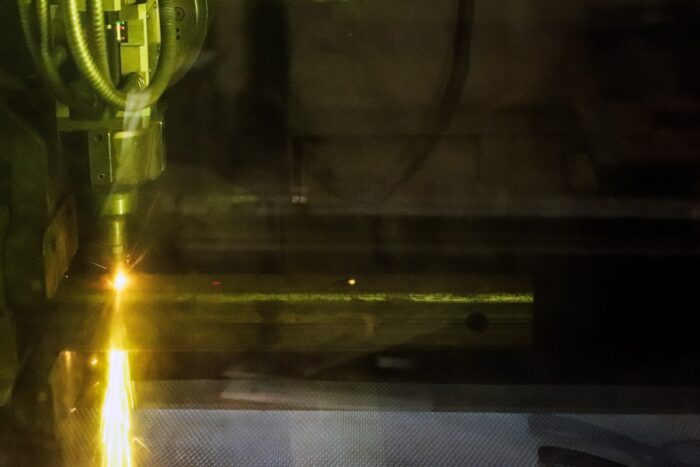

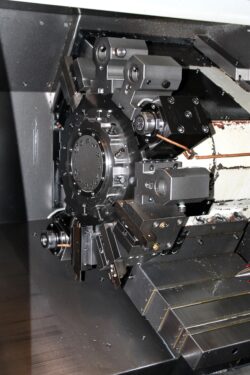

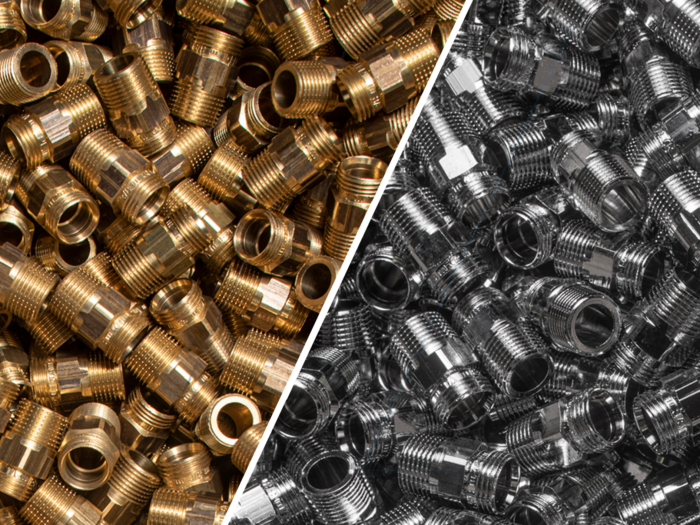

Bestnet’s machine park is one of the most modern in Estonia. A wide range of equipment allows us to perform most of the metalworking processes in-house, ensuring high product quality and delivery accuracy.

Metal industry as outsourcing

Design, CNC milling and turning, welding, laser cutting, bending and assembly

30+ years of experience

20,000+ m2 of production space

Metal structures for leading wind turbine manufacturers.

Metal structures for leading wind turbine manufacturers.

Product development and prototyping

Product development and prototyping